Mechatronics

(Honors and Dual Enrollment with Greenville Tech)

Mr. Ray Tan

Mechatronics is the backbone of modern advanced manufacturing, combining mechanical, electrical, computer, and robotics engineering into one powerful field. Students in this program learn how complex systems are designed, developed, and controlled across industries like automotive, aerospace, and automation. Because technology is advancing daily, mechatronics technicians and engineers must be adaptable, blending hands-on technical skills with problem-solving and innovation.

Our Mechatronics program is part of the South Carolina Advanced Manufacturing Career Cluster and is offered as a dual enrollment program with Greenville Technical College, allowing students to earn college credit while completing high school coursework. Students gain the entry-level skills required for advanced manufacturing and are well-prepared to continue their studies at a technical college or university.

What you’ll do:

- Read blueprints, schematics, and diagrams to plan assembly and production

- Calibrate hydraulic and pneumatic systems

- Verify precision dimensions using advanced measuring instruments

- Operate metalworking and machining tools to build parts and assemblies

- Test electro-mechanical systems using industry-standard instruments

- Install and maintain electronic components using soldering and hand tools

Certifications you can earn:

- Tier 1: OSHA-10, NCCER Core, Snap-on/NC3 Precision Measurement, YouScience Certifications (Engineering Technology, Robotics I, Electronics I)

- Tier 2: Snap-on/NC3 Multimeter 504, YouScience Robotics II

- Tier 3: Society of Manufacturing Engineers (SME) Certified Manufacturing Associate (CMfgA), Robotics in Manufacturing Fundamentals (RMF)

Students earn two high school credits each semester and up to eight credits over the two-year program. Credits count as electives toward South Carolina graduation requirements, and one credit may fulfill the CATE/Foreign Language requirement.

Visit us: Are you interested in meeting Mr. Tan and touring our Mechatronics lab? After-school tours for prospective students and parents are available in December, January, and February. We’d love to show you the program and answer any questions you may have.

Year One: Building the Foundation

Mechatronics 1 & 2 — (AM Session at Enoree)

1 Semester Honors Credit and 1 Semester Dual Enrollment Credit through Grenville Tech

Year one of the Mechatronics program introduces students to the fundamentals of advanced manufacturing and engineering technology. Open to rising 10th and 11th graders, students attend Enoree Career Center during the morning session as part of their two-year commitment. As a dual enrollment program with Greenville Technical College, students earn college credit while in high school. Training emphasizes blueprint reading, precision measurement, and the basics of mechanical, electrical, and computer systems. Students gain hands-on experience operating machining tools, testing circuits, and troubleshooting electromechanical systems with industry-standard equipment.

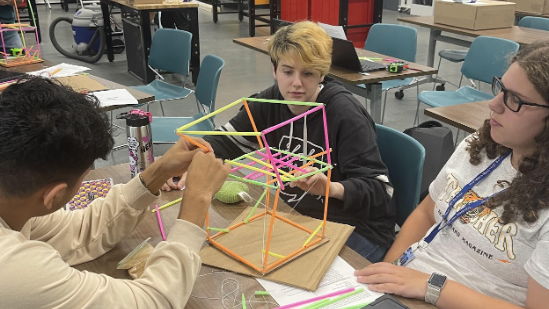

As students progress through Mechatronics 2, instruction expands into hydraulics, pneumatics, and robotics. Students learn how these systems integrate into modern production environments and practice problem-solving through real-world projects that combine design, assembly, and testing. Teamwork, safety, and professionalism are emphasized throughout, preparing students for both technical careers and engineering pathways at the postsecondary level.

By the end of year one, students will have completed core certifications including OSHA-10, NCCER Core, Snap-on/NC3 Precision Measurement, and YouScience credentials in Engineering Technology, Robotics I, and Electronics I. These certifications provide a strong foundation for the advanced training, robotics applications, and industry-recognized credentials offered in year two.

Year Two: Advancing the Skills

Mechatronics 3 & 4 — (PM Session at Enoree)

Year two of the Mechatronics program builds directly on the foundation established in year one, challenging students to apply their knowledge to advanced systems while preparing them for meaningful connections with industry partners. Students attend Enoree Career Center during the afternoon session as part of their two-year commitment, and the second year shifts the focus toward higher-level integration and application. Training emphasizes robotics programming, system-level troubleshooting, and the ability to merge mechanical, electrical, pneumatic, and computer technologies into cohesive production environments. Students also explore how automated systems are designed, maintained, and improved in real-world settings, giving them valuable insight into the demands of modern advanced manufacturing and engineering careers.

A highlight of year two is participation in work-based learning opportunities with leading local companies. Students may take part in programs such as the BMW Scholars Program, the Michelin Scholars Program, and partnerships with other local manufacturers, allowing them to apply classroom learning in professional settings. These experiences connect students to real-world production systems, expose them to employer expectations, and help them build a strong professional network before graduation.

By the end of year two, students are prepared to test for advanced certifications such as the Snap-on/NC3 Multimeter 504, YouScience Robotics II, and the SME Certified Manufacturing Associate (CMfgA), along with the Robotics in Manufacturing Fundamentals (RMF) credential. Graduates leave the program with industry-recognized certifications, direct work-based experience, and the skills to transition confidently into advanced manufacturing jobs or continue their education in engineering or related fields.

Career Opportunities

Mechanical Engineer

Mechanical engineers are those who can work on designing and planning engines and other equipment for the company. You will be in charge of equipment maintenance, installation, operation, and repair. You will get the customer design proposals, investigate failures, diagnose faulty equipment, and report to the maintenance team. You will also handle discussions and solve problems together with manufacturing departments, suppliers, and customers.

Salary - $75,352 per year on average, or $36.23 per hour

Automation Engineer

Automation engineers specialize in using technology to control the production and delivery of products. They work with automated machinery designing, programming, and testing processes. As an automation engineer, you will be employed by companies operating in mass production, such as automobile manufacturing or food processing plants, anywhere where operations are primarily carried out by robots or other automated machinery.

Salary - $92,597 per year on average, or $44.52 per hour

Electronics Engineer

An Electronics Engineer is tasked with designing, developing, examining, and even overseeing the construction and altering of electrical equipment and devices, such as generators, electrical motors, communications, and other electrical gadgets and systems, generally meant for a wide range of private and commercial needs.

Salary - $93,985 per year on average, or $45.19 per hour

Job Skills & Requirements

Each skill and trade requires a specific skill set to master the content and job tasks. Below are a few critical skills and requirements needed to succeed in the program and throughout a career in this field.

- Analytical: When examining machine parts and tools for quality assurance, tool and die makers use strong analytical and observation skills to assess the condition of each part they make.

- Blueprint reading: It is important to be able to read and interpret blueprints to create new products. These professionals also use blueprints to repair machines.

- Dexterity: Professionals in this trade use their dexterity skills when operating machinery by hand and computer.

- Flexibility: This can mean being able to adapt to material changes, different construction and design teams, new requirements for the project, and being able to communicate in a variety of ways with your clients.

- Problem-solving: Challenges can arise at any point during a project, so being able to address them quickly and effectively is an excellent skill to have as an engineer.

Available Certification Opportunities

(Click logos below for more information)

Local Work-Based Learning Partners

(Click logos below to visit our partners)

NOTE: Credits earned will count as electives needed for the SC high school graduation requirements. One of the credits earned may fulfill the CATE/Foreign Language requirement for SC high school graduation. Most 4-year colleges will NOT accept career center courses as a substitute for the foreign language college admissions requirement.